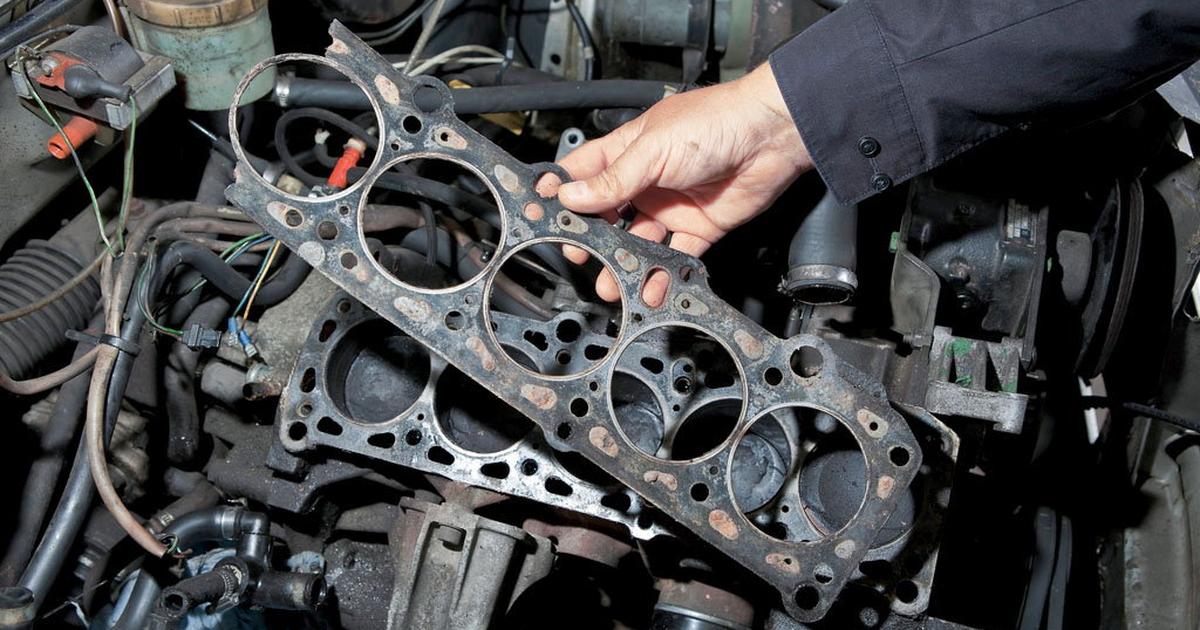

Remember that the test for damage to the gasket under the head (or the head itself) will allow you to eliminate costs of thousands of costs incurred for possible repairs.

Head gasket: causes and symptoms of the fault, repair costs

Although the head gasket is not a consumable item, its failures are very common. Moreover, its burnout is one of the worst nightmares of all drivers.

In brief

Replacing the gasket under the engine head can be quite costly - prices reach up to PLN 5,000, taking into account the purchase of this element and other damaged elements and labor. Regardless of the costs, it is not worth delaying it. It is the head gasket that is responsible for the tightness between the head and the body of the drive unit and the separation of the cooling and lubrication system pipes.

What's with the whole head gasket?

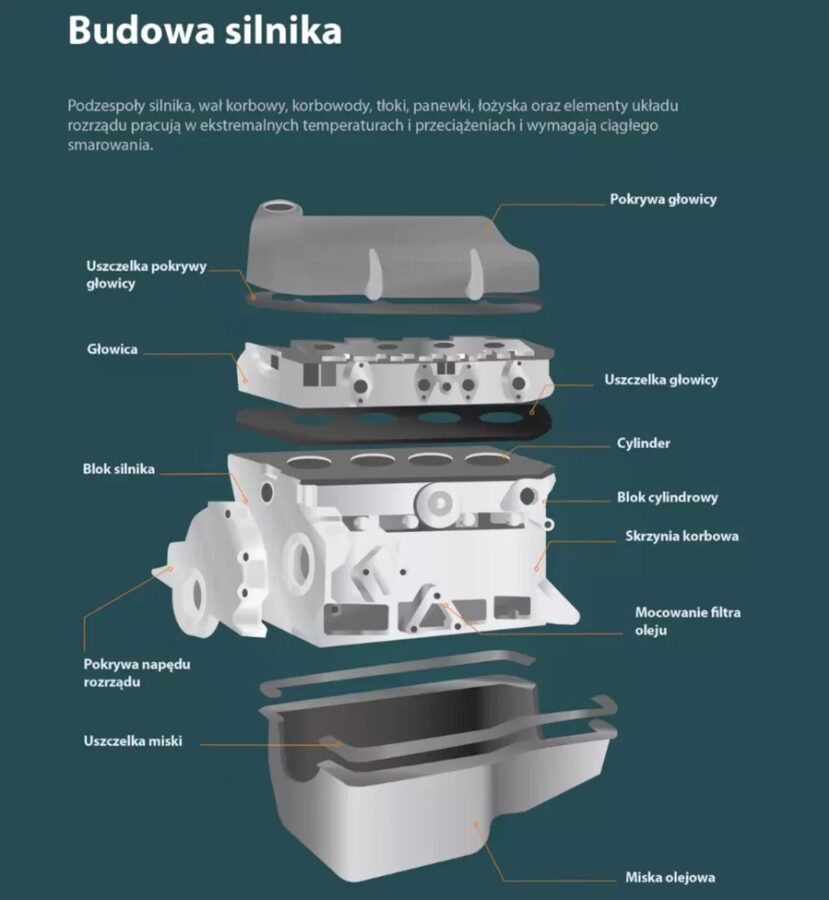

Recognizing a burnout under the head gasket is not easy - it gives symptoms that resemble some less harmful failures. Unfortunately, if ignored, it can completely destroy the engine. The gasket is responsible for the tightness of the connection between the head and the engine block. Insulates the combustion chambers and prevents loss of compression. It also separates the engine oil from the coolant and prevents the mixing of these two factors flowing in separate channels. This multifunctionality is made possible by the plasticity of the gasket: it consists largely of steel components and the holes for the soft parts cylinders located inside. The outer, harder material must be able to withstand high pressure loads and temperature fluctuations.

How to recognize the wear symptoms of the gasket?

Despite the fact that the head gasket works in an unfavorable environment, the manufacturers assume that with the absence of factory defects and proper operation of the engine, it will last for many years. In fact, it should wear at the same rate as the engine. Meanwhile, it "shoots" relatively quickly. Problematic in recognizing the symptoms of cylinder head gasket failure is their similarity to other faults. What should alert you?

- "Butter" under the oil filler cap;

- air bubbles in the coolant expansion tank;

- ejection of coolant after unscrewing the cap;

- greasy stains on the cork, signifying the ingress of engine oil into the coolant;

- rising oil level in the tank, indicating that the coolant has entered the oil;

- swelling of the cooling system hoses;

- ignition problems and a drop in engine power, resulting from reduced compression;

- uneven engine operation;

- the smell of exhaust fumes in the cabin;

- white vapor from the exhaust.

Reasons for failure of the head gasket

Sometimes there are manufacturing errors behind gasket problems. Troubles can arise when a faulty engine design causes it to overheat regularly. In fact, however, users are more likely to be to blame. It is particularly harmful for the cylinder head gasket to run at full power on a cold engine. Driving with insufficient coolant level or other oversights related to the cooling system also have negative effects. In the case of diesel engines, the cause of the fault may also be faulty injectors, and in gas-powered cars - a disrupted LPG installation.

If you notice any symptoms in your car that may indicate a worn seal, contact a mechanic immediately. Carrying out detailed diagnostics will determine whether the cause of the trouble is a significantly damaged gasket or another component.

How to deal with damage to the head gasket?

The more advanced the damage, the easier the diagnosis of a defect in the gasket is. However, as you can easily guess, further failures may mean the need to install a new gasket (and hopefully only it, not the entire drive unit!). One of the symptoms qualifying this element for immediate replacement is keeping the compression ratio at a low level. The trouble is that the replacement operation is quite complicated and usually involves additional procedures, including the planning of the cylinder head. It is a cutting process aimed at removing defects and matching the contact surface of the gasket and the sealed elements. To improve the sealing, they are sometimes attached to a special mass resistant to high temperatures. The most important and difficult point in the repair, however, is tightening the screws. This should be done with a torque wrench according to the diagram indicating the sequence and torque for tightening. Tightening is repeated a few days after inserting a new gasket.